The Beauty of Billet: Why Upgrading to a Billet Intake Grate Is a Game-Changer

In the world of personal watercraft performance, every component matters, but some upgrades deliver a bigger, more immediate impact than others. One of the most overlooked yet essential parts for handling, stability and pump efficiency is the intake grate.

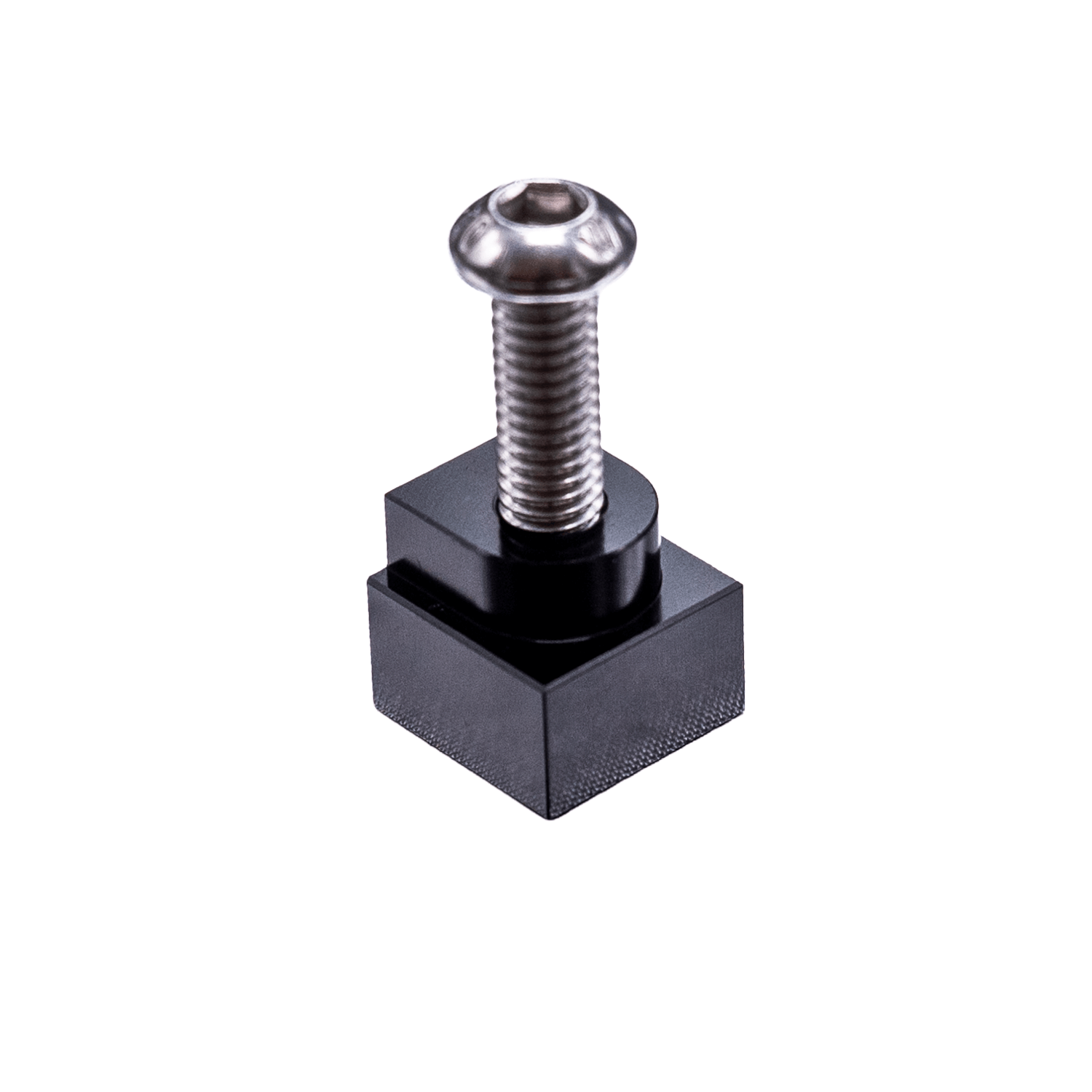

Traditional cast aluminium grates have served riders for years, but as performance expectations rise, so does the need for stronger, more reliable parts. That’s why Worx Racing is expanding its range of CNC-machined billet intake grates across select newer models, giving riders access to a new tier of strength, precision and confidence on the water.

Here’s why the move to billet makes all the difference.

1. Strength You Can Feel

Cast aluminium parts are only as strong as their mould and are often prone to impurities, porosity and inconsistent density. Billet is different. Each part is carved from a single solid block of premium-grade aluminium.

The payoff is massive.

You get:

- Increased tensile strength

- Zero internal flaws or casting impurities

- Far greater resistance to flex and impact

For riders hitting chop at speed, pushing skis harder into corners or demanding predictable handling in unpredictable water, that added strength translates into better control and more confidence every ride.

2. Precision Machining = Precision Performance

CNC machining doesn’t rely on the limits of a mould. Instead, it creates millimetre-precise water-flow geometry that cast construction simply can’t replicate.

With billet, you get:

- Sharper, more accurate leading edges

- Identical fin profiles every single time

- Pump loading that is engineered, not approximated

- Better hookup in rough conditions

- Stronger cornering performance

Every billet grate matches the CAD model exactly. No variance. No guessing. Just performance you can trust, right out of the box.

3. Superior Durability Over Time

Conditions like saltwater, cavitation and repeated impact slowly break down cast aluminium. Billet naturally resists this fatigue thanks to its dense, uniform grain structure.

This means:

- Lower risk of cracking or warping

- More predictable long-term performance

- Better corrosion resistance

- A longer life, even under aggressive riding conditions

Whether you’re racing or just riding hard on weekends, billet brings peace of mind.

4. Weight-to-Strength Efficiency

While billet components can weigh slightly more than cast pieces, the payoff is about balance, not bulk. Every extra gram is placed with intention, increasing rigidity where it matters most.

The result is the ideal blend of strength, efficiency and water-flow stability.

5. It Just Looks Better

Let’s call it what it is. Billet is beautiful.

CNC finishes. Sharp lines. Symmetrical precision. It’s engineering you can see and feel. Even tucked under the hull, riders know they’re installing something premium.

6. Better for R&D, Better for Riders

CNC machining allows Worx Racing to develop and refine designs much faster. That means:

- Quicker rollout of new models

- Stronger performance improvements every generation

- Faster expansion of our billet range

- The ability to dial in upgrades based on real rider feedback

Every new billet release represents the most advanced intake grate design we’ve produced to date.

Why Upgrade?

If you want improved handling, stronger hookup, reduced cavitation and a more reliable riding experience, upgrading from cast aluminium to billet is one of the smartest performance moves you can make.

The beauty of billet isn’t just in how it looks ... it’s in how it performs.